Processing - Structure Linkages in Semi-Crystalline Polyethylene Structures

Team Members

- Alex Lohse - MSE

- Noah Paulson - ME

Project Background

The crystallization behavior of polymers (PE) from the melt is affected by various processing conditions. Through the selection of processing paths and procedures, (e.g. blow molding) the evolution of crystallinity and crystalline orientation in polymeric materials can be controlled. These changes in structure directly affect mechanical properties of interest, therefore it is advantageous to understand how processing leads to structure in this materials system.

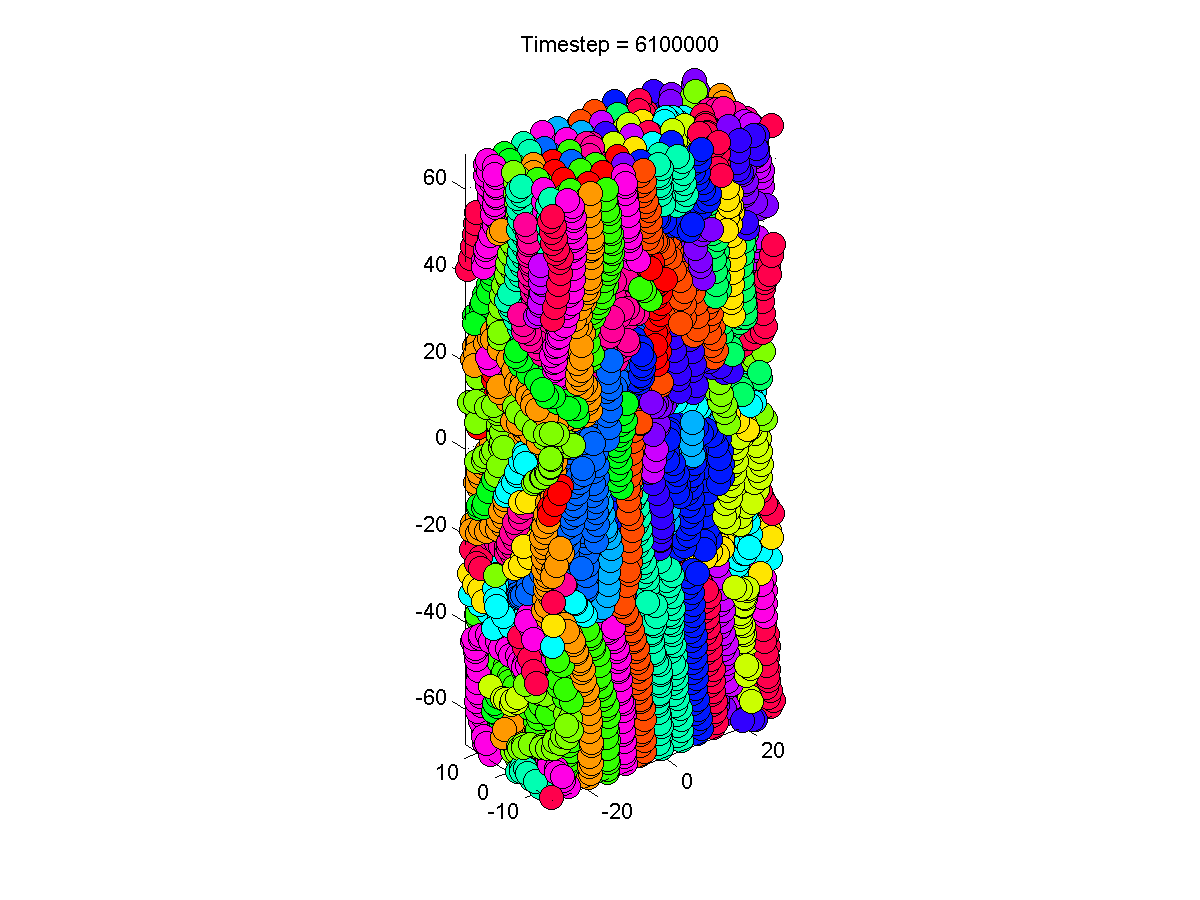

The image below, obtained by way of a molecular dynamics simulation, shows amorphous and crystalline regions in a polymeric sample

Project Goals

Characterize the linkage between processing (including material starting condition and the evolution of temperature and the stress/strain state) and structure (including the evolution of crystallinity and crystalline orientation) in semi-crystalline polyethylene.

Datasets

- Primary data generated by molecular dynamics simulations via LAMMPS

- Possible use of experimental data to verify processing-structure linkages

Proposed Workflow

- Specify microstructure function for crystallinity (connected to density and Herman’s orientation) and crystalline orientation

- Discretize the molecular dynamics datasets and post-process to extract relevant microstructural information

- Perform two-point statistics (auto and cross-correlations) on microstructure datasets at regular intervals on a variety of processing paths

- Perform principal component analysis (PCA) on the microstructure datasets and visualize in PCA space

- Generate processing - structure linkages through regressions of microstructure evolution paths in PCA space versus selected processing parameters (time, temperature, strain state, etc.)

- Validate linkage through the prediction of structure given set of processing parameters.

Visualizations of Datasets

We used codes from Tony as a guide to visualize the MD data over time.

- The codes we used are here

example of the MD data at a particular timestep

2-pt Statistics

- We wrote a trial code to demonstrate microstructure generation and 2-pt. statistics

Next Steps

- Decide on appropriate bin size to capture representation of both density and crystal orientation.

- Understand how best to track these structures through time

- Does size/number of voxels need to change in time?

- Develop code to accurately describe polymer chain vector within a specific voxel

- Use code to: calculate Herman’s orientation, crystalline orientation (through euler angles)

References

- Dong, X. et. al. Dependence of mechanical properties on crystal orientation of semi-crystalline polyethylene structures. Polymer 55 (2014) 4248-4257.

- Dong, X. et. al. Effect of network structure from different processing conditions on the mechanical property of semi-crystalline polymers. MRS Symposium, 1619, 2014.

- Fullwood, D.T. et. al. Microstructure reconstructions from 2-point statistics using phase-recovery algorithms. Acta Materialia 56 (2008) 942-948